Hansa‑flex preformed hoses for high flexibility in the tightest spaces

Preformed hoses are generally called for where conventional hose lines cannot be used because of restricted installation space. For example, in situations where a hose carrying fuel or coolant in engines or batteries would otherwise require to be bent sharply, preformed hoses from HANSA‑FLEX provide an effective and cost-efficient solution. They are highly elastic, very robust and can be made to almost any shape.

Made-to-measure preformed hoses from hansa‑flex

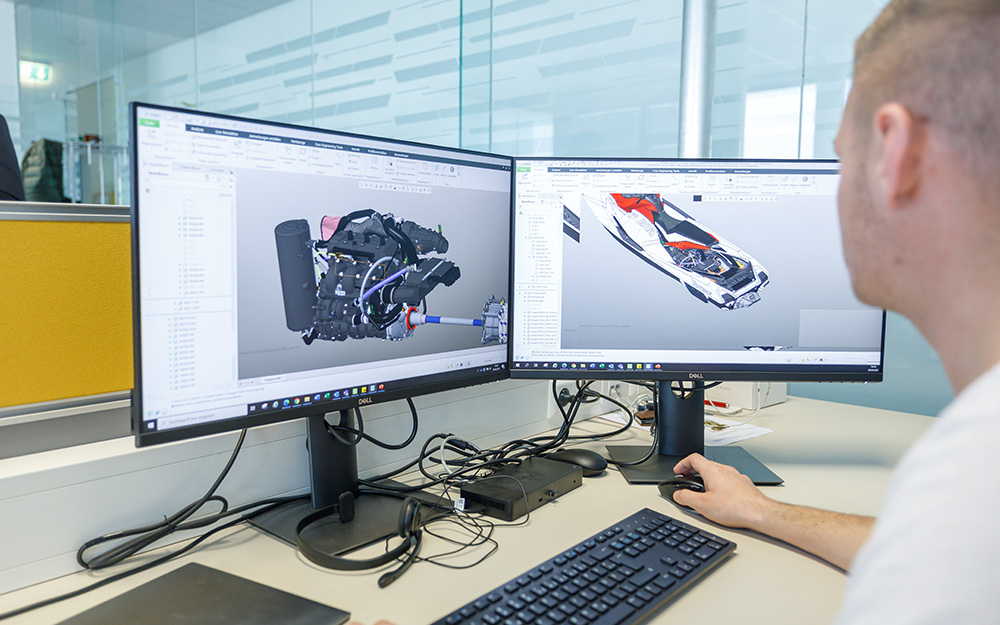

HANSA‑FLEX from design to series production readiness

HANSA‑FLEX has a large portfolio of standard preformed hoses and offers full-service solutions for customers who require individually manufactured preformed hoses to suit their precise requirements:

- Designed by the HANSA‑FLEX engineering team

- From prototyping to series production

- Optional digital determination of the XYZ data

Individual preformed hoses for all geometries

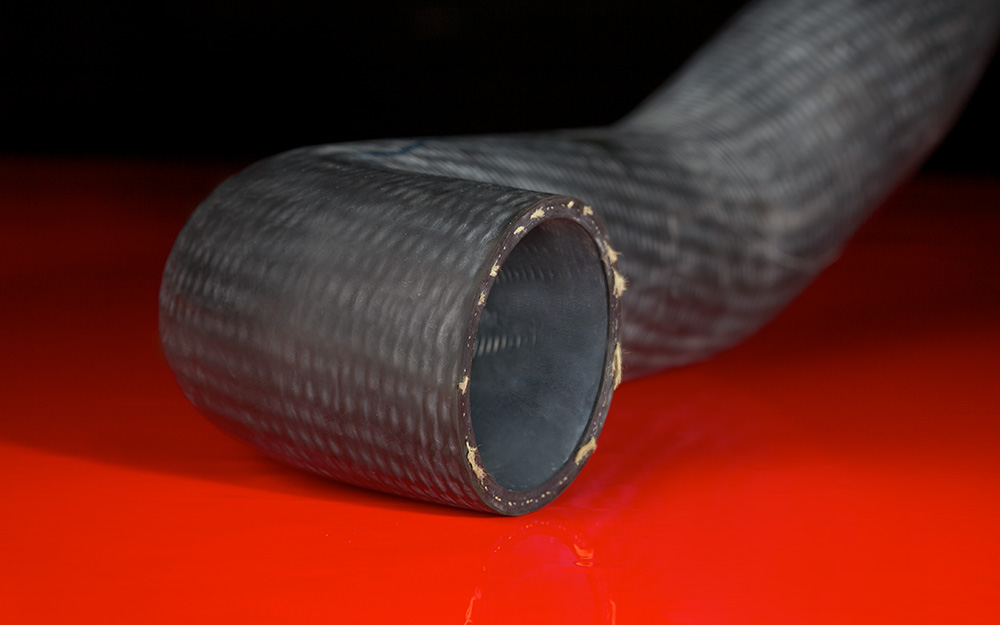

Preformed hoses must be designed and manufactured perfectly to suit their intended installation situation. Therefore, the first step is to make shaped mandrels based on the required final hose geometry in steel or stainless steel. The material for the preformed hose is then wound or drawn onto and takes up the precise geometry of the shaped mandrel. Several layers can be applied so that, for example, the inner layer of the preformed hose meets the customer’s specified media resistance requirements. Preformed hoses can be reinforced with textile or metal braid. Metal components can be vulcanised into the layers or rubber components vulcanised onto them to allow even more scope for hose design and attachment arrangements.

Preformed hoses from hansa‑flex, your innovative system partner

The HANSA‑FLEX experts with their years of experience and comprehensive knowledge of the industry can always determine the perfect shape and material mixture for any complex customer requirement.

Free-form

HANSA‑FLEX produces individualised solutions with bends of almost any radius.

Highly load resistant

Reinforcing layers for high pressure or vacuum applications can be incorporated on request.

High temperature resistance

Operating temperature ranges between -40 °C to +320 °C, depending on the material mixture.

Material mixture qualities confirmed in tests

For example, certified mixtures in accordance with DIN 73411 or fire protection standards DIN 5510 / EN 45545.

Consistent quality and long service life

Preformed hoses from HANSA‑FLEX are notable for their high load capacity, resistance to temperature and aggressive media. Material selection depends on the specific area of application

What our customers say

First-class product and service quality impresses customers all over the world.

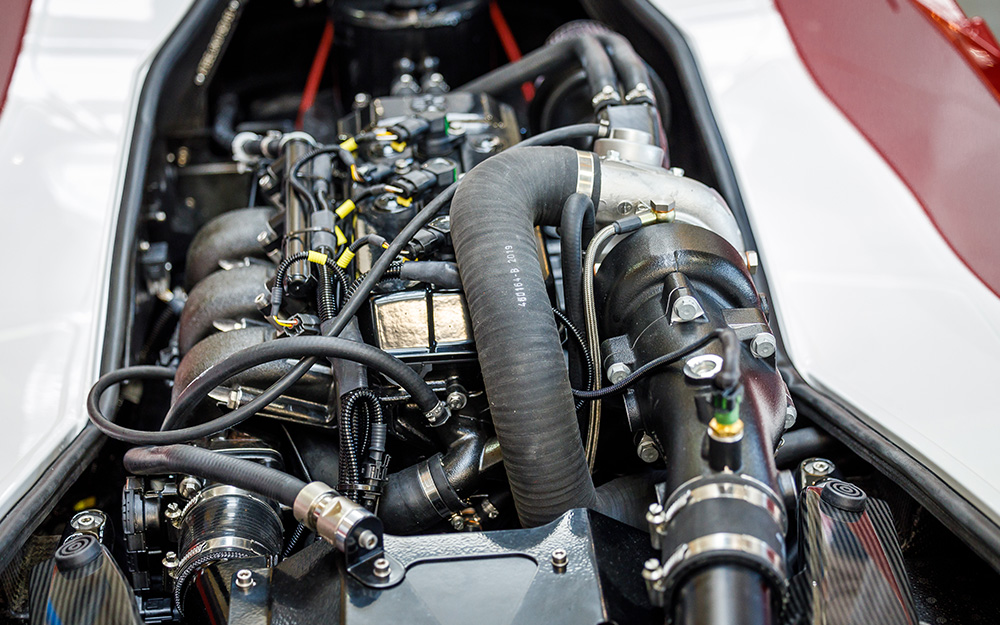

“We greatly value HANSA‑FLEX as an extremely reliable partner. We were struck in particular by the quality of the preformed hoses individually manufactured for us and the solution-focused advice we received.”

Head of Marketing and Sales, Belassi

High performance from preformed hoses

HANSA‑FLEX fits preformed hoses for fuel, coolant water and turbocharger air supply to the 320 HP Marine Hypercraft jet ski manufactured by Belassi. The preformed hoses not only have to resist the high temperatures directly on the engine, corrosive saltwater and solar radiation but also withstand the mechanical loads placed on them during the ride. Speeds of up to 120 km/h and jumping as high as 5 m into the air place special demands on hoses.

Preformed hoses made exactly to the customer’s requirements

HANSA‑FLEX perfectly matches the preformed hoses ordered by the customer to the dimensions, material requirements and field of application.

- Individualised solutions for almost any degree of bend

- Extruded or mandrel-wrapped to suit the specific application

- Reinforced with polyester or rayon fabric inserts

- Preformed hoses can incorporate several inlets/outlets

These hansa‑flex products may also be of interest to you

Pipelines

The HANSA‑FLEX range of pipeline products includes expansion joints, bent pipes and special fittings for liquids, gases and coolant water. HANSA‑FLEX’s state-of-the-art manufacturing…

Find out moreIndustrial hoses

Industrial hoses find application where the medium is not used for transmitting power. Industrial hoses transport a wide range of…

Find out moreExtremely high-pressure hoses

HANSA‑FLEX extremely high-pressure hoses are always the first choice in systems where elevated pressures prevail. Indeed, they may have to cope…

Find out more