Hydraulic accumulators are pressure compensation vessels and energy buffers

Pressure accumulators are used as pressure compensation vessels and balance temperature-related changes in volume and pressure peaks in hydraulic systems. Acting as a buffer accumulator, they also absorb the energy caused by pressure changes and release it later when necessary. They are also used to safely compensate for leaks , dampen pulsations and absorb shocks in systems and machines.

Gas-filled pressure accumulators from hansa‑flex

The HANSA‑FLEX range includes numerous diaphragm and bladder accumulators in various designs. We can also supply you with other accumulated types, such as piston accumulators or individually manufactured special accumulators on request.

Bladder accumulators for large oil volumes

Bladder accumulators consist of a high-strength pressure vessel and a sealed bladder, which can be filled with gas. These accumulators are notable for their high speed of reaction and rapid return of fluid to the system.

- 1 l to 50 l oil volume

- Permitted working pressure up to 350 bar

- Fluctuations are quickly equalised

Robust diaphragm accumulators

Diaphragm accumulators consist of a spherical pressure vessel and are robust against external forces. Diaphragm accumulators are used for applications with smaller volumes of oil.

- 0.075 l to 1.4 l oil volume

- Working pressure 100 to 350 bar

- Low-temperature application version for use down to - 40 °C available

Required equipment and suitable accessories

The HANSA‑FLEX online shop has numerous products, such as adapters, nuts and repair kits, for the mounting and safe operation of your pressure accumulator.

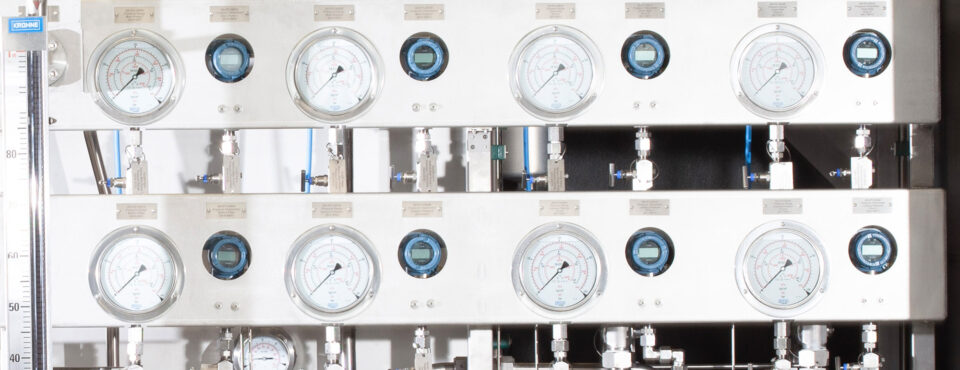

- Safety and isolation blocks for making safe and depressurising

- Accumulator brackets and clamps for mounting

- Inspection and filling equipment for checking the nitrogen pressure

Expert advice

A pressure accumulator can fail for a great many reasons. Our HANSA‑FLEX specialists are always pleased to advise you.

“The ratio the operating pressure of the system and the gas charge pressure in the accumulator must be within the range specified by the manufacturer. Too great a pressure difference or large pressure fluctuations can lead to damage of the membrane or bladder.”

Product Manager at HANSA‑FLEX

The benefits of using oil-hydraulic accumulators from hansa‑flex

High quality

All pressure accumulators are manufactured by renowned European companies.

No compromise on safety

Pressure accumulators meet with the requirements of the European Pressure Equipment Directive (PED).

Certified products

Supplied with the appropriate European or international approval certificates.

Advice from experts

We support you in the selection and design of accumulators suitable for your application

High-quality pressure accumulators from the fluid specialists

All pressure accumulators are delivered ready to install from stock. On request, we can install your accumulator and fill it with nitrogen on site.

- Permissible temperature for bladder accumulators: - 15 ℃ to + 80 ℃

- Permissible temperature for diaphragm accumulators: - 40 °C to + 80 °C

- Material for bladder and diaphragm: NBR standard grade

- Material for diaphragm low-temperature version: ECO

- Connections: Internal or external threads

How a pressure accumulator works

Pressure accumulators use the compressibility of nitrogen to absorb and store energy. An expanding elastomeric diaphragm or bladder divides the vessel into separate volumes for gas and oil. The gas side of the hydraulic accumulator is pressurised with gas at the required pressure before the system starts operation. If the fluid side of the system become subject to increasing pressure, the pressures in the two sides are equalised by the movement of the separating component and compression of the gas. The result is equilibrium between the gas and fluid pressure, and fluid is admitted into the accumulator. As soon as the hydraulic pressure drops, the compressed gas expands and pushes the fluid back into the hydraulic circuit.

Training and seminars on pressure accumulators in hydraulic systems

In cooperation with the International Hydraulics Academy (IHA), HANSA‑FLEX runs seminars for installation engineers and pressure accumulator maintenance personnel. Experts pass on their specialist knowledge of the safe operation, proper filling and repair of pressure accumulators.

These topics may also be of interest to you

Pressure accumulator inspection

Pressure accumulators are among the systems that need to be monitored by law and must therefore be checked regularly by…

Find out morePressure accumulators and associated systems

Safe and reliable operation of pressure accumulator systems depends on regular maintenance including checks on the filling level and pressure…

Find out moreDrive and control technology

Hydraulic components fulfil the highest quality standards at HANSA‑FLEX, where quality management has DIN ISO 9001 certification. Availability is ensured by…

Find out more